manual d hvac

Understanding HVAC Manuals⁚ A Comprehensive Guide

HVAC manuals are crucial for efficient system design, installation, and maintenance. They provide detailed specifications and operational procedures, ensuring optimal performance and longevity. Understanding these manuals is key for both professionals and homeowners.

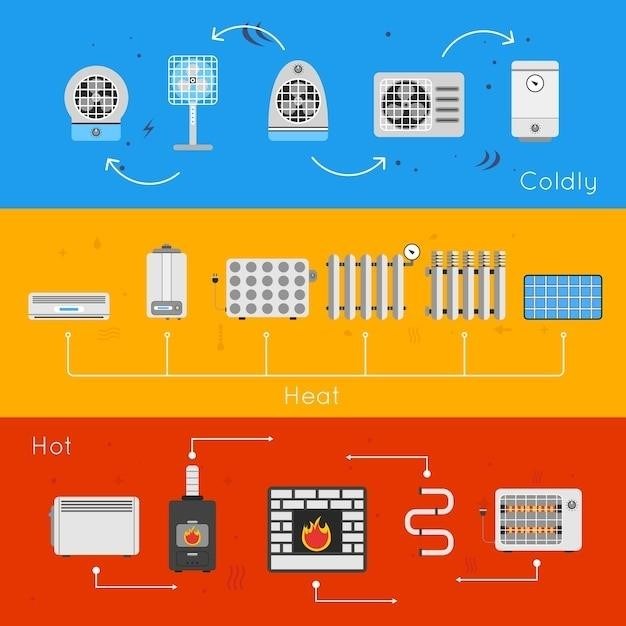

HVAC manuals serve as comprehensive guides for the design, installation, operation, and maintenance of heating, ventilation, and air conditioning systems. These manuals are essential tools for HVAC technicians, engineers, and even homeowners. They contain vital information about system components, safety procedures, troubleshooting techniques, and performance optimization strategies. Understanding and utilizing HVAC manuals are crucial for ensuring efficient and safe operation, preventing costly repairs, and maximizing the lifespan of HVAC equipment. Whether it’s a manufacturer’s manual providing specific instructions for a particular model or an industry standard like Manual D focusing on duct design, these resources are indispensable for anyone working with or owning an HVAC system. Proper use of these manuals can significantly improve indoor air quality, energy efficiency, and overall comfort.

Types of HVAC Manuals⁚ Manufacturer’s Manuals vs. Industry Standards

The HVAC industry utilizes two primary types of manuals⁚ manufacturer-specific manuals and industry-standard manuals. Manufacturer’s manuals provide detailed instructions for installing, operating, and maintaining specific equipment models. These manuals are crucial for technicians working on particular brands and models, offering precise specifications, diagrams, and troubleshooting guides tailored to the equipment’s design. In contrast, industry-standard manuals, such as those published by ACCA (Air Conditioning Contractors of America) or ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), offer generalized guidelines and best practices applicable across various systems. These standards, like Manual D for duct design, establish benchmarks for system performance, efficiency, and safety. While manufacturer manuals focus on specific equipment, industry standards provide broader, universally applicable principles and calculations, ensuring consistent quality and performance across the industry. Both types of manuals play essential roles in ensuring successful HVAC installations and maintenance.

ACCA Manuals⁚ J, S, D, and T ⸺ A Deep Dive

The ACCA (Air Conditioning Contractors of America) publishes several crucial manuals for HVAC professionals. Manual J focuses on load calculations, determining the heating and cooling requirements of a building. This ensures the system is appropriately sized for optimal efficiency. Manual S guides equipment selection, matching the calculated loads from Manual J with suitable HVAC units. This precise matching guarantees the system’s capacity meets the building’s needs. Manual D, the subject of our focus, details duct design, optimizing airflow for even heating and cooling throughout the structure. Proper duct sizing and design, as outlined in Manual D, prevents energy waste and ensures occupant comfort. Finally, Manual T addresses the thermal performance of the building envelope, influencing the efficiency of the chosen system. Together, these manuals provide a comprehensive approach to HVAC system design, ensuring proper sizing, selection, and distribution of air, leading to energy efficiency and improved indoor environmental quality. Using these manuals in conjunction guarantees a well-designed and efficient HVAC system.

ASHRAE Handbooks⁚ Fundamentals, Applications, and Equipment

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) publishes comprehensive handbooks that serve as industry standards for HVAC design and operation. The “Fundamentals” handbook provides a thorough grounding in the theoretical underpinnings of HVAC systems, covering thermodynamics, psychrometrics, heat transfer, and other essential concepts. This foundational knowledge is critical for understanding the principles behind efficient system design. The “Applications” handbook delves into the practical application of these fundamentals, offering guidance on designing systems for various building types and climates. It addresses the specific requirements of different applications, considering factors like occupancy, building materials, and environmental conditions. Lastly, the “Equipment” handbook details the specifications and performance characteristics of various HVAC equipment components, offering a detailed understanding of their operation and selection criteria. Together, these handbooks offer a complete resource for HVAC professionals, providing the theoretical framework and practical applications needed for designing high-performing, energy-efficient systems that meet the specific needs of any building. They are considered the definitive resource for HVAC best practices.

HVAC System Design and Installation

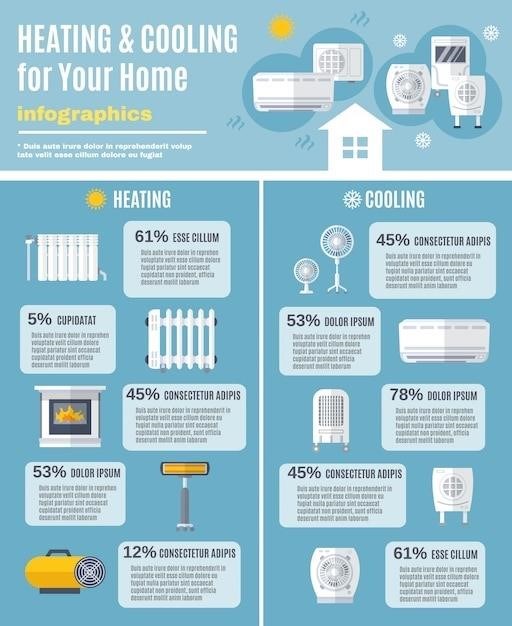

Proper HVAC system design and installation are critical for optimal performance and energy efficiency. These processes involve careful consideration of various factors to ensure a comfortable and functional indoor environment.

Manual J⁚ Load Calculations for Efficient Sizing

Manual J, a cornerstone of HVAC design, focuses on accurately calculating the heating and cooling loads of a building. This crucial step ensures that the selected HVAC system is appropriately sized for the specific needs of the structure. Oversized systems lead to short cycling, reduced efficiency, and increased energy consumption, while undersized systems struggle to maintain comfortable temperatures. Manual J takes into account various factors, including climate data, building materials, insulation levels, window types, and occupancy patterns. Detailed calculations determine the necessary heating and cooling capacity to maintain desired indoor temperatures. The results directly influence the selection of HVAC equipment in subsequent steps, such as the equipment selection outlined in Manual S. Accurate load calculations using Manual J are essential for creating a cost-effective and energy-efficient HVAC system, avoiding both underperformance and unnecessary energy waste. By meticulously considering these factors, Manual J helps ensure that the chosen HVAC system delivers optimal comfort and efficiency throughout the year. Ignoring Manual J’s guidelines can result in significant energy losses and reduced occupant satisfaction. The precision of Manual J’s calculations underpins the entire design process, impacting the overall performance and cost-effectiveness of the HVAC installation.

Manual S⁚ Equipment Selection Based on Load Calculations

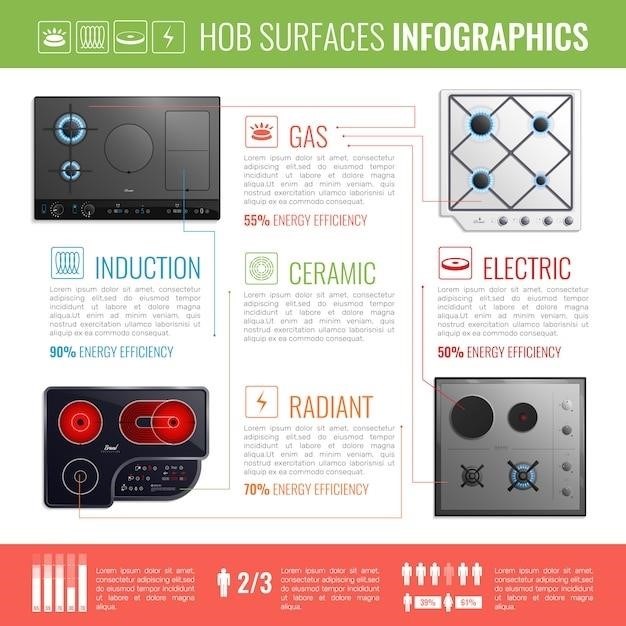

Manual S, the next critical step after Manual J’s load calculations, guides the selection of appropriate HVAC equipment. This manual uses the heating and cooling load data generated by Manual J to determine the right size and type of furnace, air conditioner, or heat pump for a specific building. It ensures that the chosen equipment can effectively meet the calculated heating and cooling demands, preventing both undersized and oversized systems. Manual S considers factors beyond just BTU ratings, including efficiency levels (SEER, AFUE), airflow requirements, and compatibility with the ductwork system (as designed in Manual D). The selection process involves comparing various equipment models based on their performance characteristics and efficiency ratings to find the optimal balance between cost, energy efficiency, and performance. Incorrect equipment selection can result in significant energy waste, reduced comfort, and increased maintenance costs. Manual S emphasizes selecting equipment that efficiently delivers the heating and cooling capacity calculated in Manual J, ensuring optimal system performance and energy efficiency. The process ensures the right balance between initial investment, long-term operating costs, and overall system reliability, directly impacting homeowner comfort and operational expenses. Accurate selection, guided by Manual S, optimizes the efficiency of the entire HVAC system.

Manual D⁚ Duct Design for Optimal Airflow

Manual D is the essential guide for designing efficient and effective duct systems in HVAC installations. It focuses on ensuring proper airflow throughout the building, delivering the calculated heating and cooling loads precisely to each room as determined by Manual J and the equipment selected in Manual S. This manual details the precise sizing of ducts, including main supply and return plenums, branches, and registers, to minimize pressure drops and ensure uniform air distribution. Factors considered include duct material, shape, length, and the number of bends, all of which influence airflow resistance. Proper duct design is critical for achieving the desired temperature and humidity levels in every room, preventing uneven heating or cooling, and maximizing the efficiency of the HVAC system. Inadequate duct design can lead to significant energy loss, reduced comfort, and increased operating costs due to oversized equipment working harder to compensate for airflow restrictions. Manual D ensures that the duct system is appropriately sized and designed to work seamlessly with the HVAC equipment, delivering the required air volume at the correct pressure. This meticulous approach results in a comfortable and energy-efficient indoor environment. Following Manual D’s guidelines minimizes energy waste and enhances the overall performance of the HVAC system.

HVAC System Operation and Maintenance

Proper HVAC operation and maintenance are crucial for system longevity and energy efficiency. Regular cleaning, filter changes, and inspections are essential for optimal performance and indoor air quality;

Regular Maintenance and Cleaning Procedures

Regular maintenance is vital for optimal HVAC system performance and longevity. This includes frequent filter changes, as dirty filters restrict airflow, reducing efficiency and potentially damaging the system. Cleaning the evaporator coil and condenser coil is also crucial. These coils accumulate dust and debris, hindering heat transfer and decreasing efficiency. A professional cleaning, ideally annually, ensures thorough removal of dirt and grime. Inspecting ductwork for leaks or damage is essential for maintaining proper airflow and preventing energy loss. Addressing any issues promptly prevents further problems and ensures the system operates at peak efficiency. Regular maintenance significantly extends the lifespan of your HVAC system, reducing the need for costly repairs or premature replacements. Remember to consult your specific HVAC system’s manual for detailed cleaning and maintenance instructions tailored to your model and type.

Troubleshooting Common HVAC Problems

Troubleshooting HVAC issues starts with identifying the problem. Is the system not producing sufficient heating or cooling? Are there unusual noises emanating from the unit? Is the system cycling on and off too frequently? These symptoms often indicate specific issues. A lack of cooling might point towards a refrigerant leak, a malfunctioning compressor, or a dirty condenser coil. Insufficient heating could be due to a faulty heat exchanger, a malfunctioning blower motor, or a problem with the gas supply (for gas furnaces). Unusual noises, such as rattling or banging, often indicate loose components requiring tightening or replacement. Frequent cycling could signify a problem with the thermostat, airflow restrictions, or a failing capacitor. Before attempting any repairs yourself, consult your system’s manual for safety precautions and guidance. For complex issues, contacting a qualified HVAC technician is crucial to avoid further damage or safety hazards. They possess the expertise and tools to diagnose and resolve the problem efficiently and safely.

Safety Precautions and Emergency Procedures

Prioritizing safety during HVAC system operation and maintenance is paramount. Always disconnect the power supply before performing any maintenance or repair work. Never work on a live system; electricity poses a significant risk of electrocution. When handling refrigerants, wear appropriate personal protective equipment (PPE), including gloves and eye protection, to prevent skin and eye irritation or exposure to harmful chemicals. Proper ventilation is crucial when working with refrigerants to avoid inhaling toxic fumes. Be mindful of sharp edges and moving parts within the HVAC system; cuts and injuries can occur if precautions aren’t taken. If you detect gas leaks (in gas-powered systems), immediately shut off the gas supply and ventilate the area. Never attempt to repair gas leaks yourself; contact a qualified gas technician. In case of electrical shocks or fire, immediately cut off the power supply and evacuate the premises. Contact emergency services and inform them of the situation. Regular inspection of electrical connections and wiring is crucial to prevent electrical hazards. Always follow the manufacturer’s instructions and safety guidelines provided in the HVAC system manual. Familiarize yourself with emergency shut-off procedures before any maintenance tasks.